3D printers are creating our future. You can make anything from small plastic toys to concrete homes and single printers have begun to replace traditional factory production lines. They can even create moving parts like wheels, chains, and gears. The only question is…How do they work?

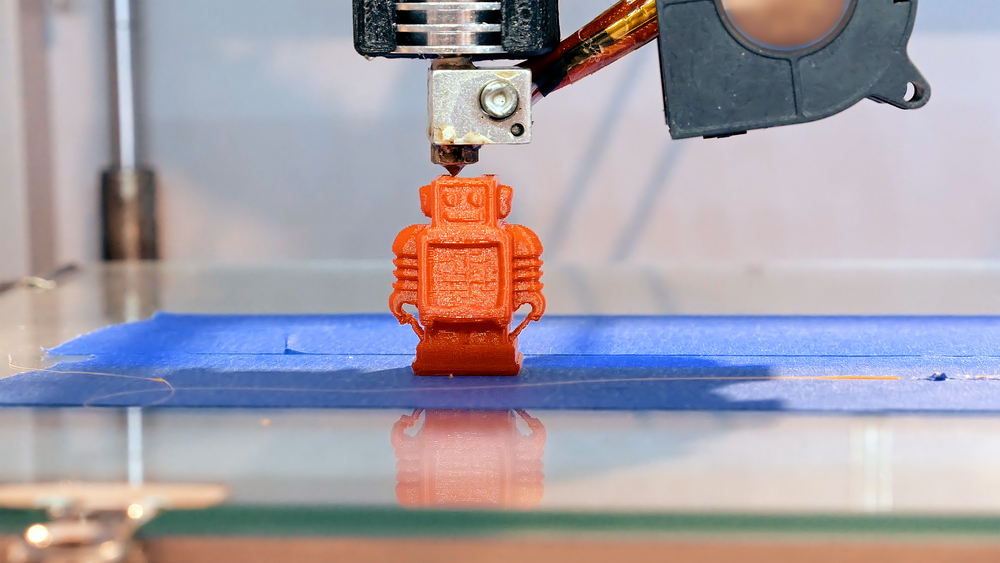

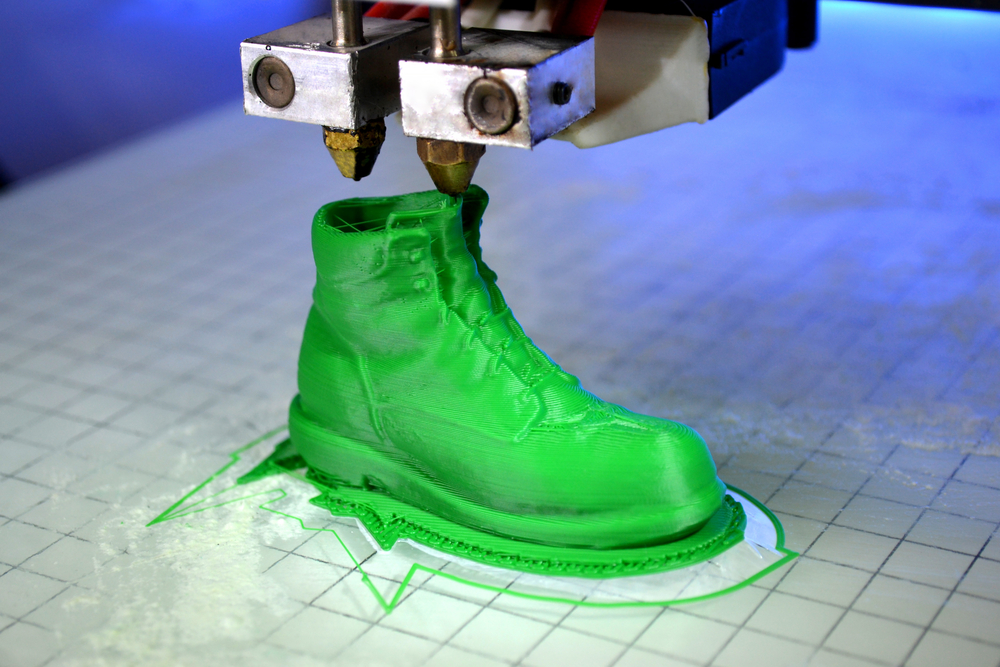

The best way to think of how a 3D printer works is to think of objects in flat 2D layers. A 3D printer must print each layer in a fine plastic and when you stack each layer on top of one another, you have your final product. For smaller pieces, such as a thimble, you may need around 40 layers. For larger pieces such as an action figure, it might take hundreds of layers to construct.

Although today’s 3D printers have different variations, the base idea behind each printer pulls from the original idea of melting and forming the product. In one of the world’s first 3D printers, created in the 1980’s, machines worked in a way that is very similar to how they work today:

- The computer hooked up to the printer communicates what the user would like to print.

- The printer begins to start laying plastic, or whatever material is selected to create the product, onto a base-plate underneath the printer’s head.

- The base-plate is able to move horizontally to maximize space and the printer head and nozzle move vertically as the object being created is printed upwards.

- Raw materials, such as plastic rods, are inserted and melted by the print head. They are then heated with a thermocouple attached to the printer head and heat sensor.

- Using compressed air the raw materials are extruded from the nozzle.

What can we expect to see within the future of 3D printing? This process, though it is relatively expensive, is becoming cheaper and more readily available to the consumer. The real future of 3D printing can be seen within the manufacturing industry, where it will have a multitude of economic benefits including conserving labor, decreasing cost, and increasing production. It will also increase the craftsmanship of many items we currently have on the market. This makes 3D printing something that is very positive for the economy, manufacturers, and us.